SESSA

Japanese SME Business and

Innovation Network for Medical DevicesSESSA uses the advanced technology of its member companies to supply innovative, high-quality medical devices, to medical device manufacturers worldwide, along with components and subassemblies for medical devices.

Bringing the World

Innovative Medical Devices

- Ultraprecision machining technology from small and medium Japanese enterprises

- Japanese material technology

- The experience and skills of medical device experts

SESSA is a Japanese SME business and innovation network for medical devices. Established in 2014, it comprises small and medium manufacturing companies in Japan.

The small and medium Japanese companies belonging to SESSA include manufacturing companies that offer internationally competitive ultraprecision processing technology, a company manufacturing excellent materials including the world's strongest stainless steel, and an ODM where medical devices are developed by highly experienced and skilled engineers.

SESSA's Business Model

SESSA works with medical device manufacturers in Japan and overseas, creating medical device businesses in the Japanese and global markets with the outstanding products of small and medium Japanese manufacturers.

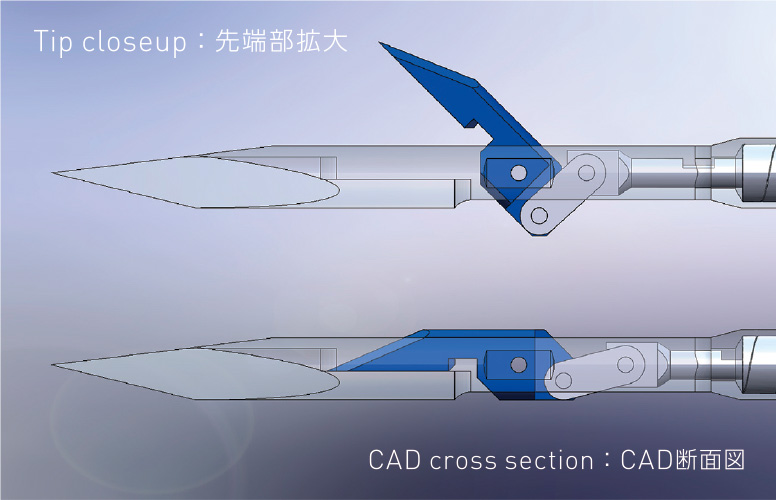

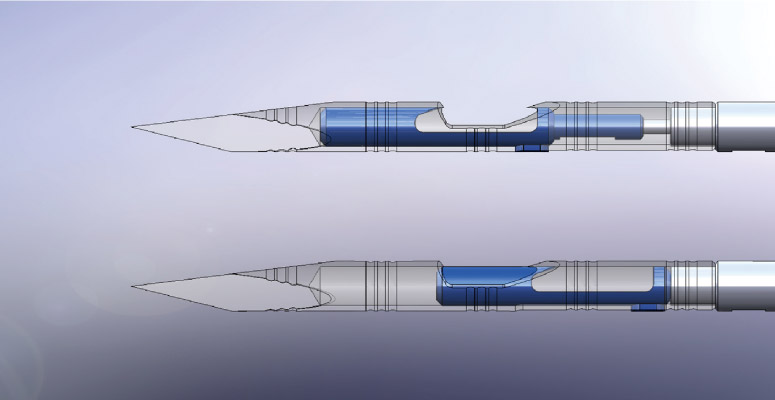

Prototype example φ1.1mm EUS-FNB biopsy needle for endoscopes

The prototype biopsy needles for EUS-FNB endoscopes produced by SESSA are biopsy needles for ultrasonic endoscopes that aim to collect tissue from lesions with simple opening and closing movements, similar to biopsy forceps. The prototypes were produced based on joint research with Dr. Hashimoto of the National Cancer Center Japan.

- Aims of the φ1.1mm EUS-FNB ultrasonic biopsy needle prototype

-

〔Pinpoint collection of specimens for histological diagnosis〕

The sharp blade and cup of the biopsy forceps allow reliable extraction of lesion tissue.

-

〔Easy operation〕

The agitation, stylet insertion/removal and suction that are performed when using standard ultrasonic biopsy needles are not required.

-

〔Easy endoscope insertion and removal〕

The highly flexible sheath structure facilitates insertion and removal of the needle from the endoscope.

-

〔Straightness during centesis〕

The needle tip has a symmetrical design, allowing straightness to be maintained during centesis.

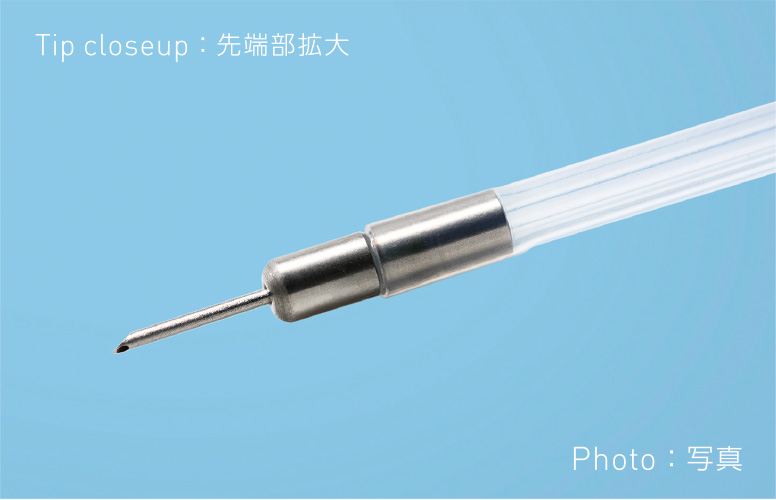

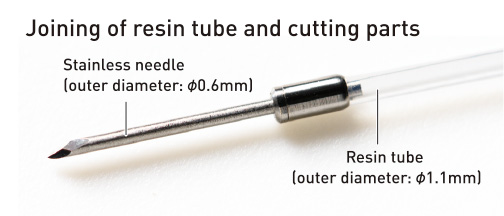

Prototype example φ0.6mm submucosal injection needle

The tip of the injection needle has a specially designed cross-section, aimed at providing reliable selective local injection to the submucosa. The prototype was produced based on joint research with Dr. Tashiro of Osaka Medical College and Dr. Aoyagi of Kansai University.

- Aims of the φ0.6mm submucosal injection needle prototype

-

〔Pinpoint injection〕

As the opening for liquid delivery is only in the tip of the needle, injections to the submucosa can be made with pinpoint accuracy.

-

〔Easy operation〕

Liquid leakage to the mucosal surface is reduced even when using the same operation methods as for standard endoscopic injection needles, allowing submucosal injections to be carried out in a shorter time.

-

〔Easy endoscope insertion and removal〕

The highly flexible sheath structure facilitates insertion and removal of the needle from the endoscope.

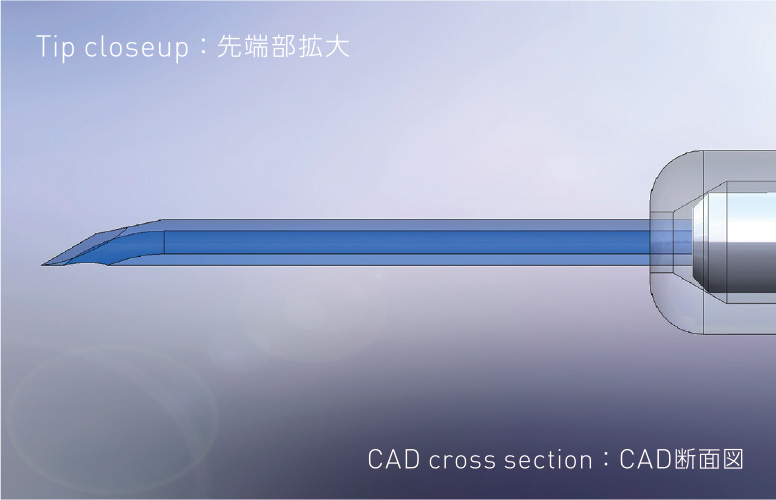

Prototype example φ0.9mm EUS-FNB biopsy needle for endoscope

- Aim of SESSA's Prototype

-

〔Pinpoint collection of specimens for histological diagnosis〕

Side holes with dual sliding blades enable reliable collection of lesions.

-

〔Easy operation〕

Does not require the agitation, stylet insertion or suction that is performed in a standard ultrasonic biopsy.

-

〔Easy to insert in and remove from endoscopes〕

The flexible sheath structure enables the needle to be inserted in and removed from the endoscope more easily.

-

〔Straight puncturing〕

The needle has a highly symmetrical design, enabling it to move in a straight line when puncturing.

Prototype example Needle for local injection of submucosa

This local injection needle holds mucous membrane with a grip at the end, enabling selective, reliable injection from the submucosa.

This local injection needle holds mucous membrane with a grip at the end, enabling selective, reliable injection from the submucosa.

It was developed jointly by Dr. Keitaro TASHIRO at Osaka Medical College, Prof. Seiji AOYAGI at Kansai University, and SESSA.

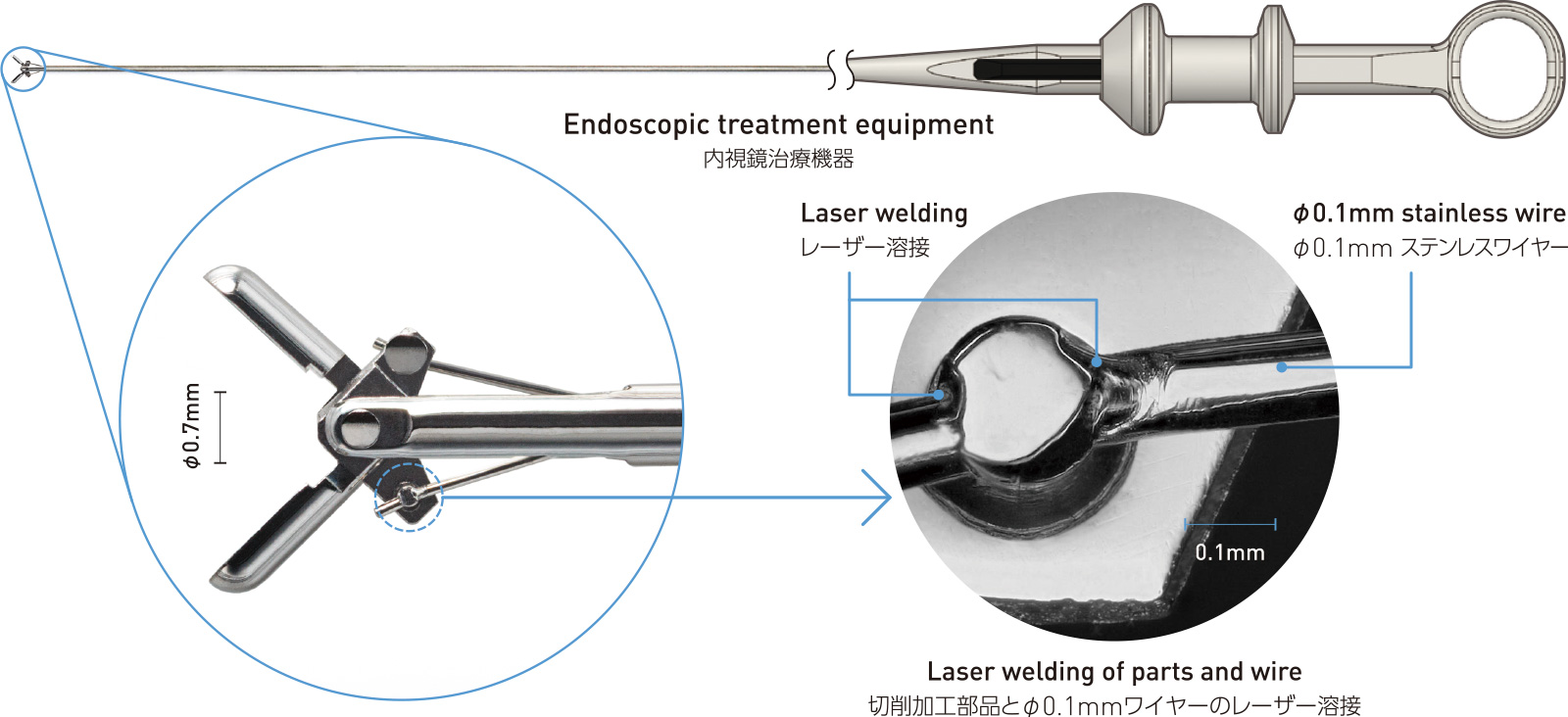

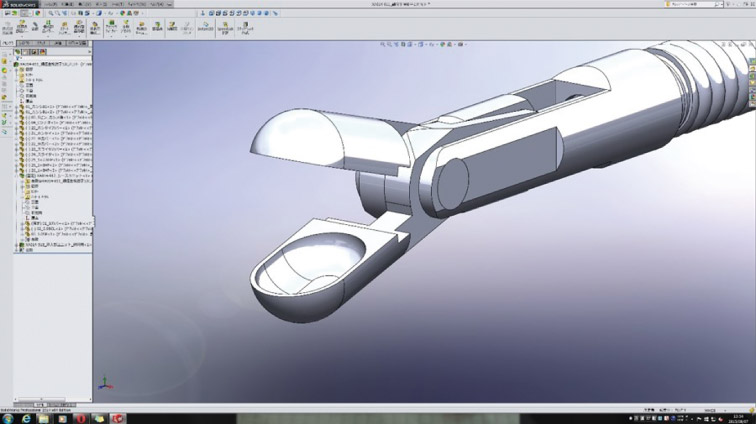

Prototype example φ0.7 mm forceps for respiratory endoscopes

These biopsy forceps have a finer diameter than any other pair of respiratory endoscope forceps in the world. Made from ultrafine-grained stainless steel with superior strength and ductility, these forceps were developed using SESSA's precision processing and assembly technologies.

These biopsy forceps have a finer diameter than any other pair of respiratory endoscope forceps in the world. Made from ultrafine-grained stainless steel with superior strength and ductility, these forceps were developed using SESSA's precision processing and assembly technologies.

ODM and development

- ODM and development contractor for medical devices

- nano grains Co., Ltd.

Materials

- Material technology for ultraprecision devices

- Komatsuseiki Kosakusho Co., Ltd.

Processing

- Ultrafine precision coil technology

- MIKURO SPRING Co., Ltd.

- Precision specialized alloy tubes

- Propox Co., Ltd.

- Precision polishing technology for inner surfaces

- KYOEI DENKO Co., Ltd.

- Precision coating technology

- MIZOGUCHI Co., Ltd.

Processing and subassembly

- Precision joining technology

- KYOSHIN Co., Ltd.

Processing and assembly

- Precision processing and assembly technology

- Takashima Sangyo Co., Ltd.

- ODM and development

- ODM and development contractor for medical devices

nano grains Co., Ltd.

ODM and development contractor for medical devices

nano grains responds to the development and manufacture of medical equipment according to customers' requirements.

Customers can also outsource strategic planning, marketing, etc. of medical equipment. Engineers who have extensive experience in medical device development help our customers.

- Examples of medical devices we design

-

- ●Endoscopy instruments

- ●Forceps for endoscopic surgery

- ●Other medical devices

Contract development of quantitative evaluation systems

for medical devices

Quantitative evaluation of medical equipment before a medical doctor's evaluation of medical equipment lead to a more correct and deeper understanding of the evaluation contents received from the doctor.

Customers can confirm superior numerical data such as superiority over existing products, and can promote the development of medical devices efficiently.

nano grains is entrusted with the development of an evaluation system for medical devices that are difficult to quantitatively evaluate.

- Materials

- Material technology for ultraprecision devices

Komatsuseiki Kosakusho Co.,Ltd.

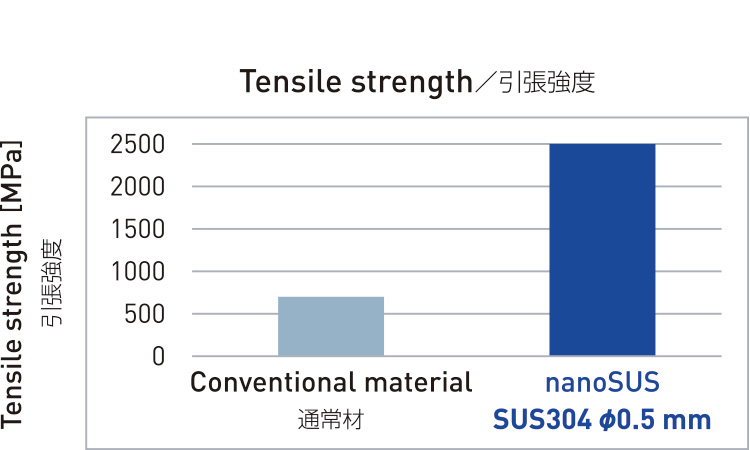

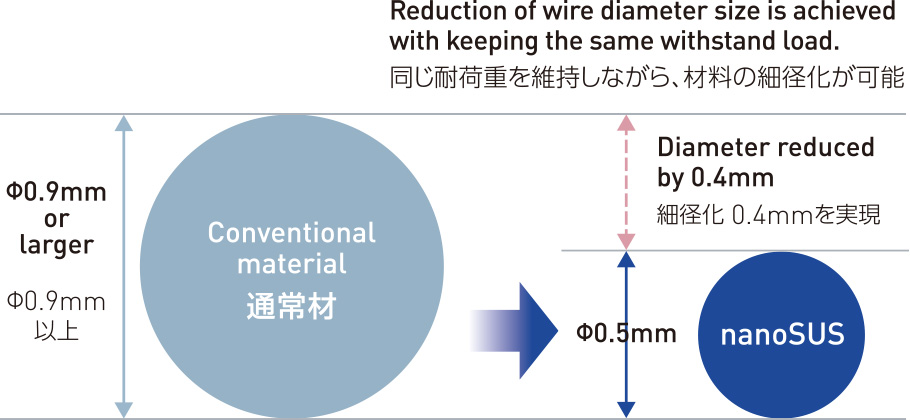

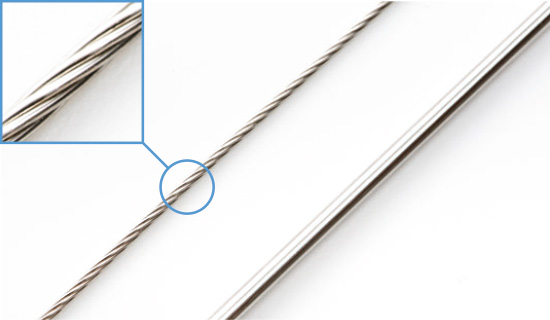

nanoSUS®, the world's strongest ultrafine grained stainless steel

Komatsuseiki Kosakusho Co., Ltd. is the only manufacturer in the world that has succeeded in mass-producing ultrafine grained stainless steel with an average grain size class of 0.5 μm.

"nanoSUS" improves tensile strength up to 2.5 times and hardness by up to 30% compared with conventional stainless steel. In general, high strength / high hardness stainless steels are poor in processability, but in nanoSUS, it has been confirmed that processability is improved compared to conventional stainless steel.

Because the chemical composition of "nanoSUS" is not changed from that of conventional stainless steel, it is also easy to use for medical equipment.

- ● Products available

- Wires and rods:

φ0.04mm~φ2.6mm

- ● Standard complied of available products

- SUS301 (ISO: X5CrNi17-7)

- SUS304 (ISO: X5CrNi18-10)

- SUS316 (ISO: X5CrNiMo17-12-2)

- SUS420J2 (ISO: X30Cr13)

- *Contact us for details on other shapes, dimensions and materials.

- *nanoSUS is produced under a patent held by the National Institute for Materials Science. JP-4714828-B2

- *nanoSUS is a registered trademark of Komatsuseiki Kosakusho Co., Ltd.

- Processing

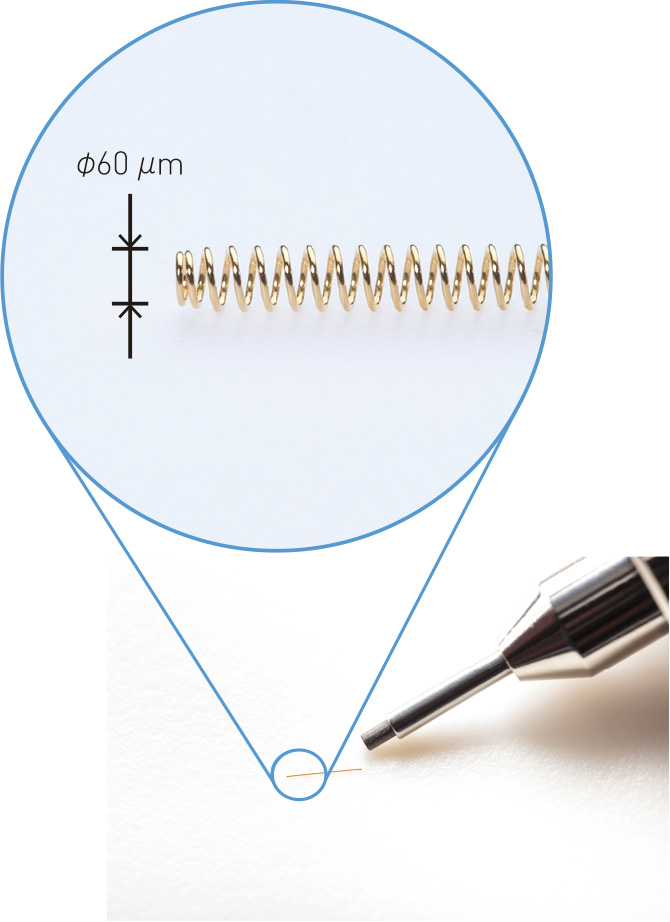

- Ultrafine precision coil technology

MIKURO SPRING Co., Ltd.

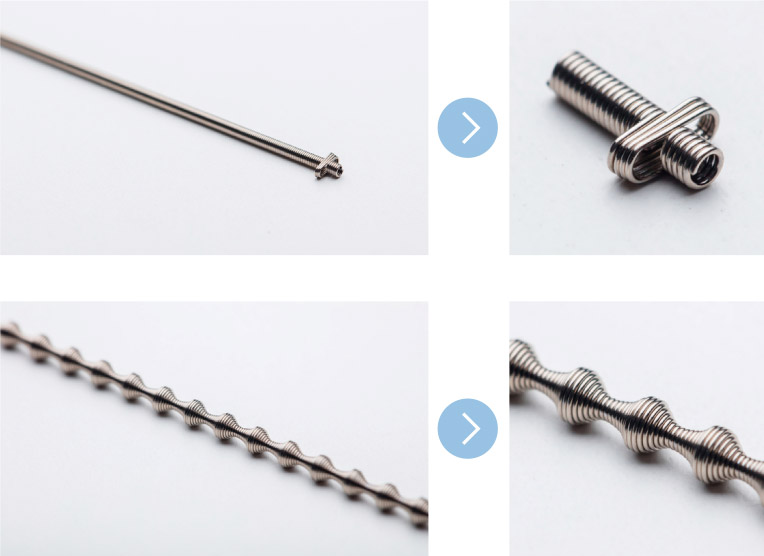

Micromachining-based technology for producing ultra-fine springs

MIKURO SPRING Co., Ltd. produces springs for a variety of medical devices according to customer needs.

Our state-of-the-art ultra fine spring production methods allow the creation of some of the world's smallest springs, with outer diameters as small as φ60μm. Please contact us for more information.

Adding new functions to springs

MIKURO SPRING Co., Ltd. creates new functions for springs by adding new technology to conventional spring processing technology.

-

- Springs with a non-circular cross section

MIKURO SPRING Co., Ltd. creates new functions for springs by adding new technology to conventional spring processing technology.

MIKURO SPRING Co., Ltd. creates new functions for springs by adding new technology to conventional spring processing technology.

-

- Resin coating

Our technology now enables resin coating to be applied to ultra-fine springs, which provides a new function for protection against electrical currents passing along the spring.

Our technology now enables resin coating to be applied to ultra-fine springs, which provides a new function for protection against electrical currents passing along the spring.

- Processing

- Precision specialized alloy tubes

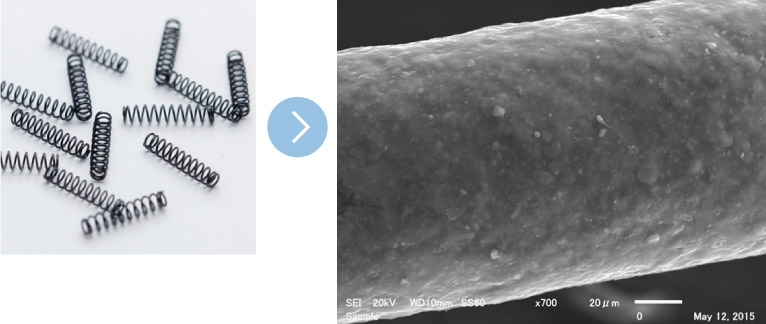

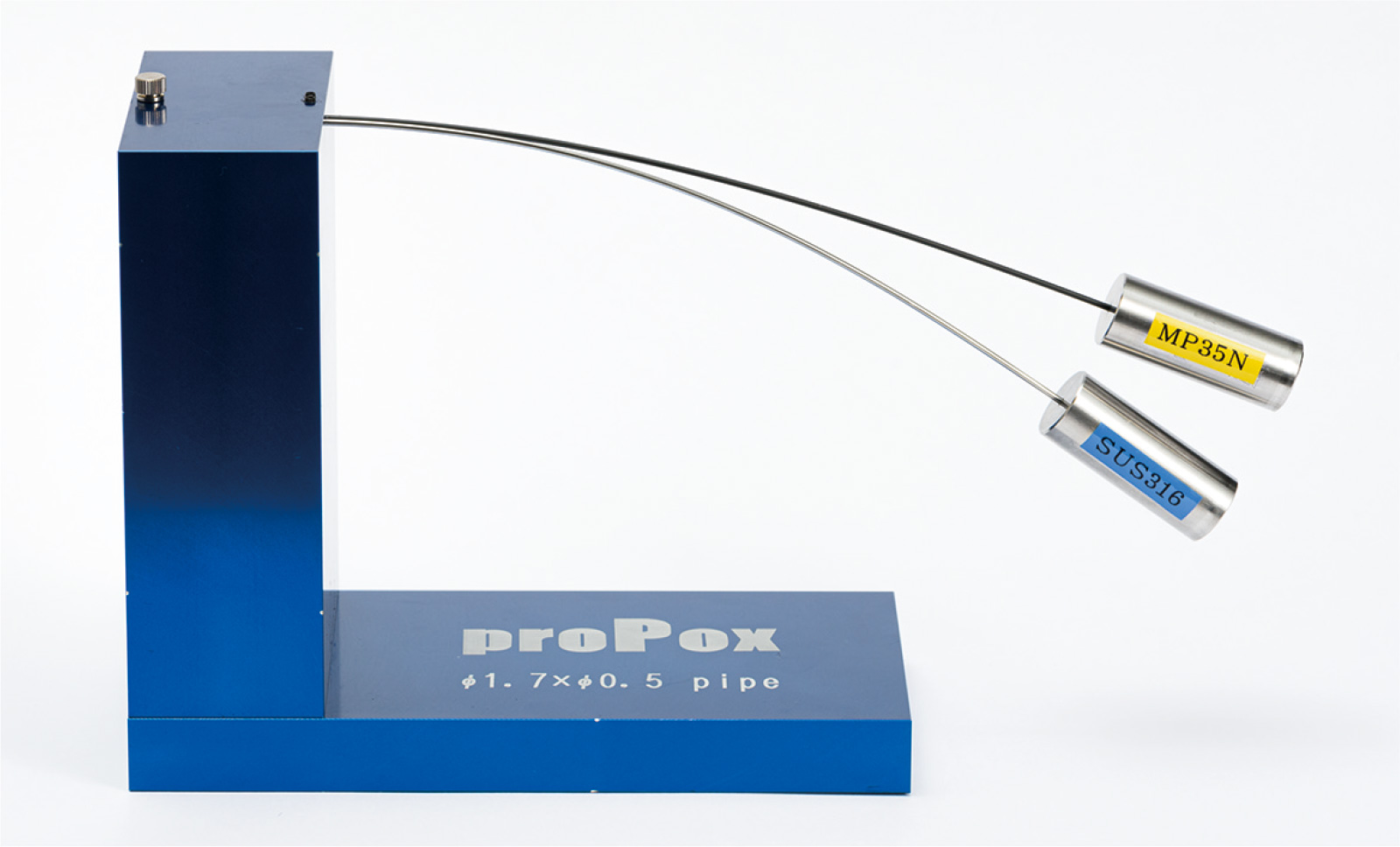

Propox CO.,LTD.

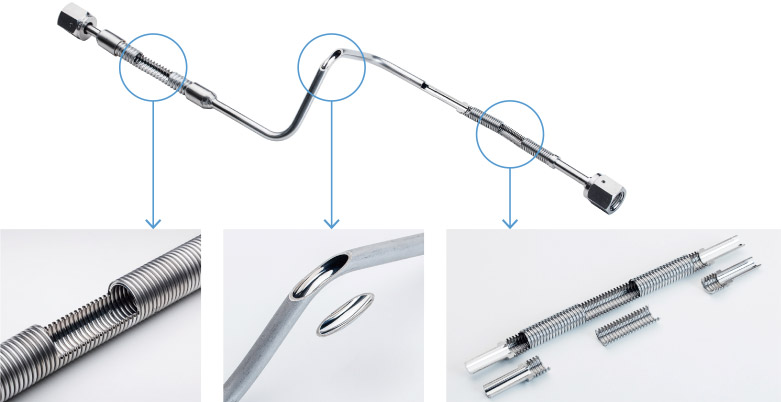

Providing precision specialized alloy tubes with outstanding strength and durability

MP35N® and Elgiloy® alloy tubes are produced using our unique technology, which focuses on the 4Ms (Material, Machine, Method, Man) that are critical in tube manufacturing. Created using a nickel-cobalt based multiphase alloy system, they offer ultra high strength, toughness, ductility and excellent corrosion resistance, making them suitable for use in demanding environments in the medical field. We are also able to offer a variety of solutions by making use of a combination of technologies, including material development, ultra precision machining, tube inner surface polishing and fine wire.

MP35N, Elgiloy alloy tubes

MP35N and Elgiloy are age-hardenable (to 700Hv) nickel-cobalt-based alloys that provide a unique combination of extremely high strength, toughness, ductility and outstanding corrosion resistance. They exhibit crevice corrosion resistance and stress corrosion cracking resistance in hydrogen sulfide, salt water, and other chloride solutions. Their strength, high elastic modulus and good corrosion resistance make them suitable materials for use in medical devices and dental products.

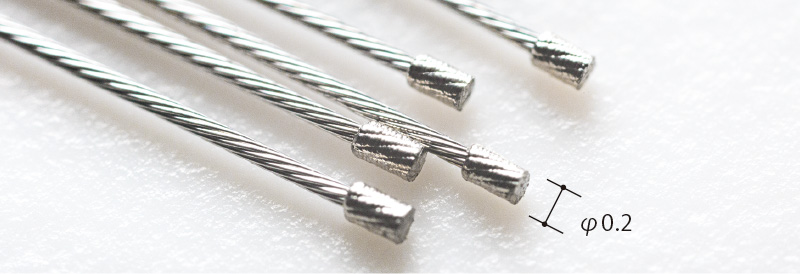

Pull wire

An ultra fine wire that is inserted inside a catheter and pulled by the tip. Nickel plating is applied to the tip and the stepped structure prevents a drop in tensile strength due to heat such as from laser welding (patent pending). SUS304 is used as standard, however, it is also compatible with the stronger MP35N and Elgiloy, in addition to any tubing with a wire diameter of φ0.09 or greater.

*Elgiloy® is a registered trademark of Elgiloy Specialty Metals.

- Processing

- Precision polishing technology for inner surfaces

KYOEI DENKO Co., Ltd.

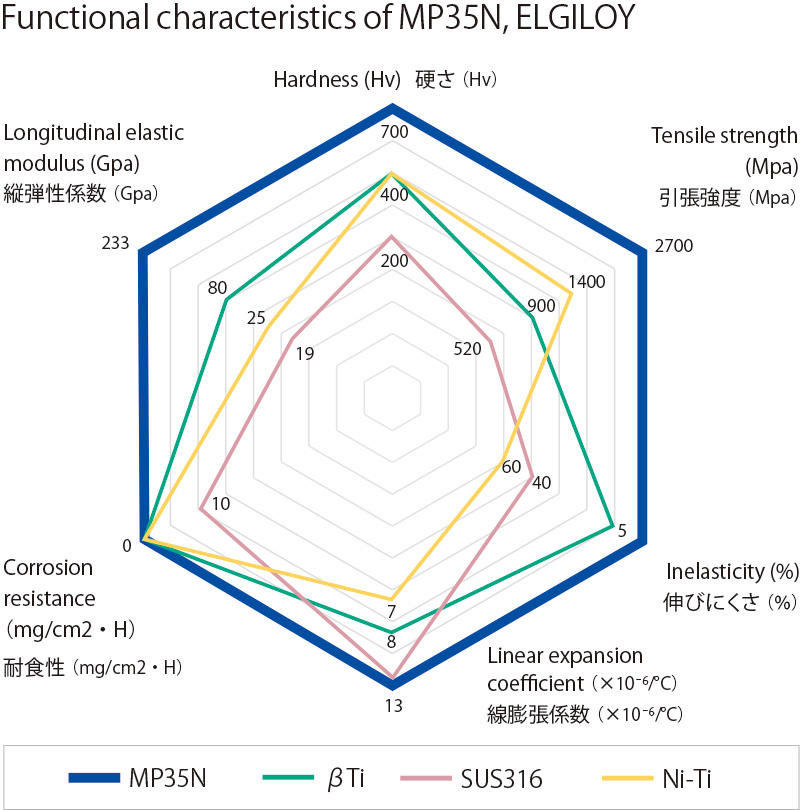

Ultra-precision polishing to mirror finish

Our unique ultra-precision polishing technology has achieved a mirror finish on the surfaces of deformed tubes, tapered tubes, and tubes with different diameters, which a difficult or even impossible to polish with conventional technology.

Compared with unpolished or electro-polished tubes, tubes with ultra-precision polished surfaces dramatically reduce turbulent flow in fluids passing through the tubes and reduces risks of cross contamination by drops of fluid from the pipes. Using this tube enables more reliable test results at medial facilities.

A mirror finish can be applied even on flexible tubes with a discontinuous interior wall at their crests, sides, and trough (material: SUS316L).

Comparison of polished inner surfaces inside the cylinders (material: SUS316L): Our ultraprecision polishing can be applied not only to SUS but to ceramic and titanium tubes.

Comparison of polished inner surfaces inside the cylinders (material: SUS316L): Our ultraprecision polishing can be applied not only to SUS but to ceramic and titanium tubes.

- Processing

- Precision coating technology

MIZOGUCHI Co.,Ltd.

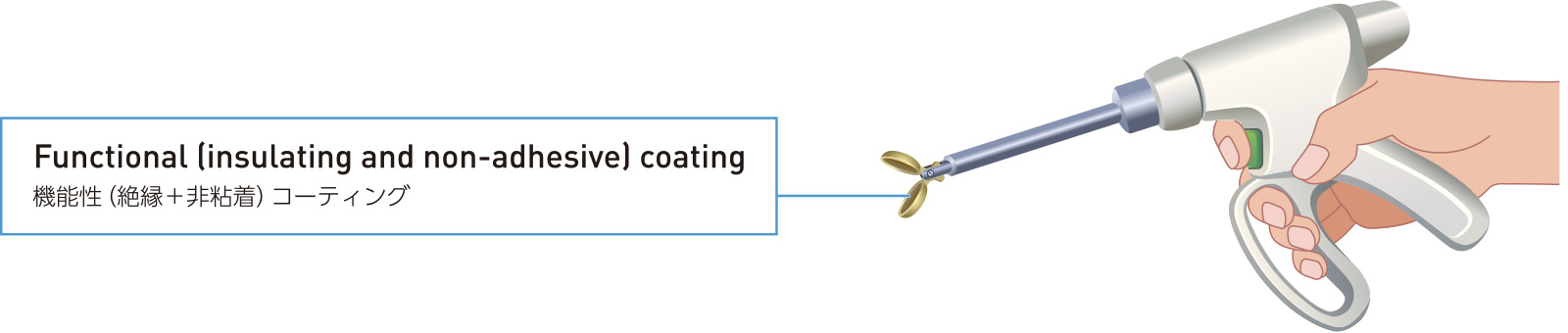

Multifunction coating for medical device parts

Using our high-quality coating technology,

we meet the varied needs of medical device manufacturers.

Super Engineering Plastics Coating (SEP Coating)

SEP coating is an innovative new printing technology developed by our company. Compared with conventional coating, it provides the following advantages.

- ● Reduced costs as less material is required for coating.

- ● Since masking is not required, intricate curves and edges can be finished neatly.

- ● Film thickness can be easily controlled.

Printing examples : PEEK. PTFE. PFA.

PEEK (Polyether ether ketone) printing

"Printing" is only performed on parts that require PEEK resin, which is often used on parts for medical devices. It can also be used for coating. Despite being plastic, it can be used continuously at temperatures of 250℃, and provides excellent heat resistance, chemical resistance, abrasion resistance, slidability, and insulation.

- Distal end of endoscopic surgical equipment

※The above functional coating is made with coating technology from MIZOGUCHI Co., Ltd.

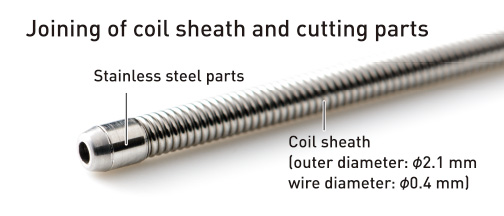

- Processing and subassembly

- Precision joining technology

KYOSHIN Co., Ltd.

Precision Cutting and Joining Technology

Our high-precision cutting technology and unique joining technology using cold plastic deformation enable the joining with the following characteristics.

- ●Joining without the adverse effects of heat

- ●Joining of dissimilar materials

- ●Joining with flexible parts

- ●Joining with very little variation in strength

- ●Watertight joining

Example applications

Joining technology suitable for use in medical devices such as endoscopic instruments and catheters.

- Precision fine cutting parts

-

Integrated manufacturing from high-precision cutting to assembly

- Precision processing and assembly technology

- Processing and assembly

Takashima Sangyo Co., Ltd.

We have technologies for small parts processing and assembly

- ● Takashima Sangyo provides ultra-precision processed parts by using various technologies such as cutting, laser manufacturing, polishing and chemical treatment.

- ● We manufacture medical equipment using micro-assembly technology and micro-laser welding technology.

Ultra precision machining

Ultra precision assembly